Selected Project

Some Projects Truly Show the Benefits of Surveying Techniques Combined with the Latest in UAS Technology. This Project is One of Them!

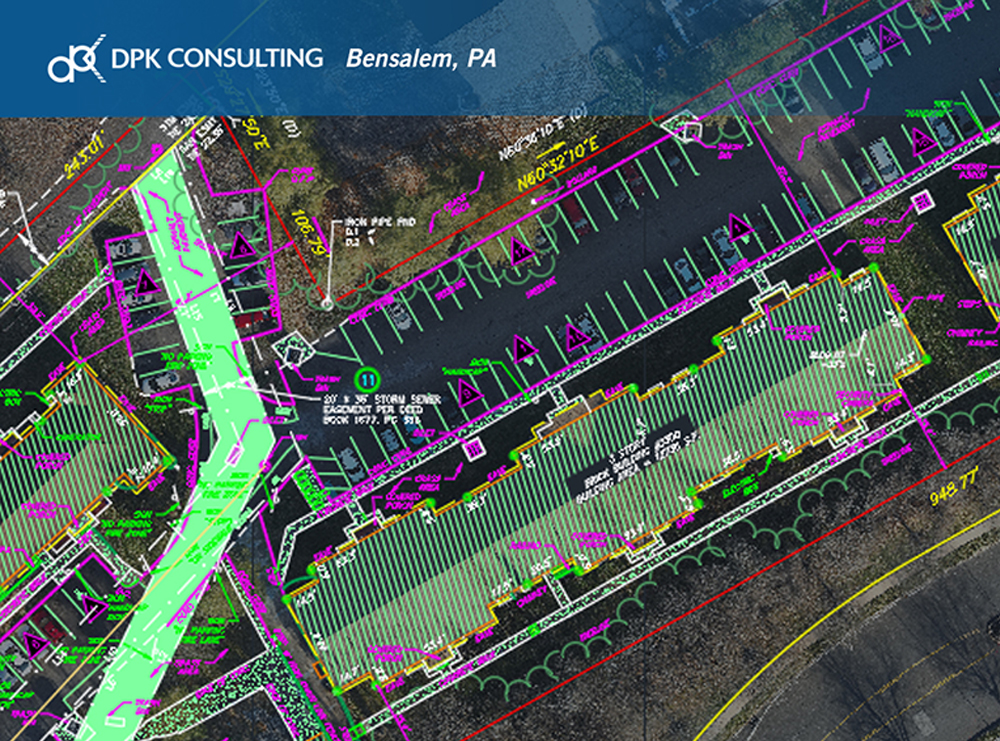

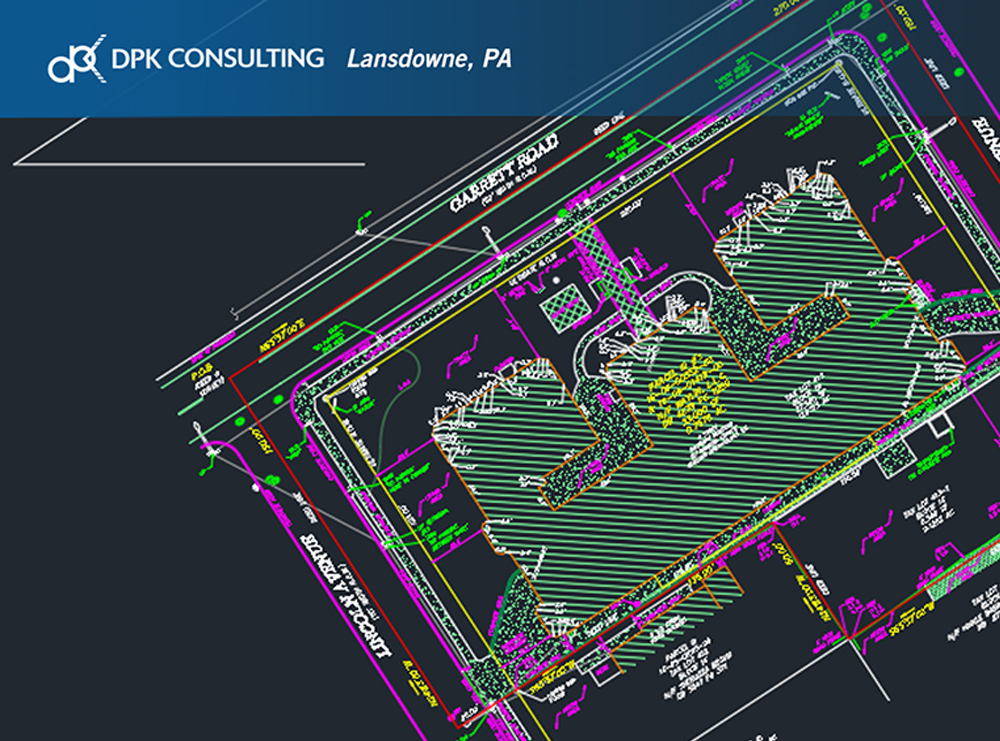

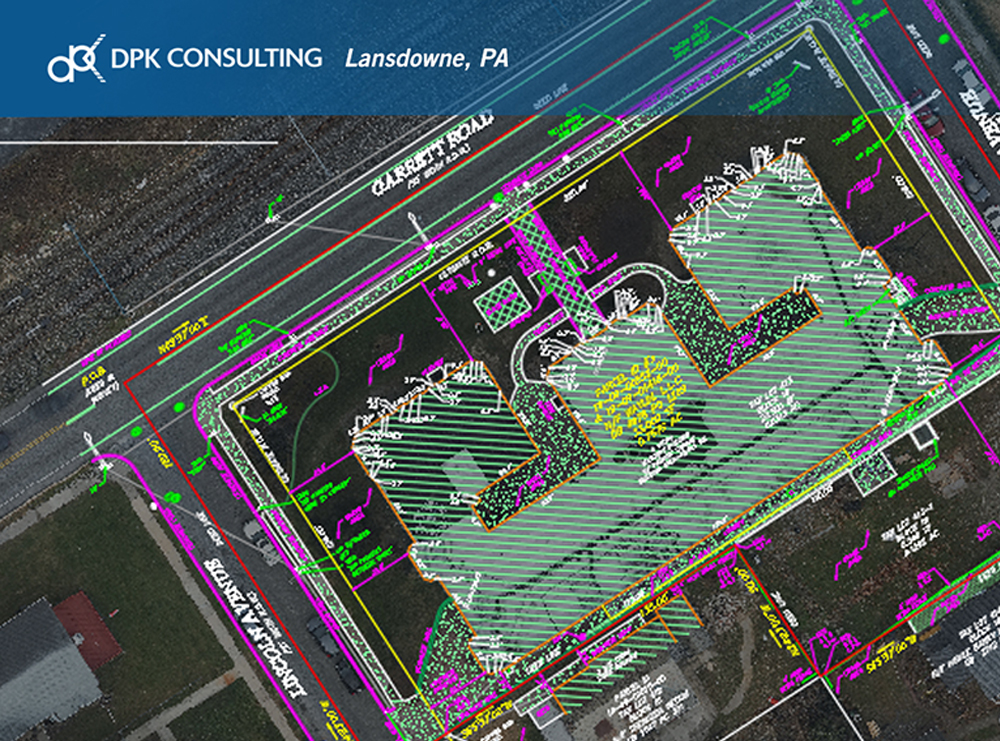

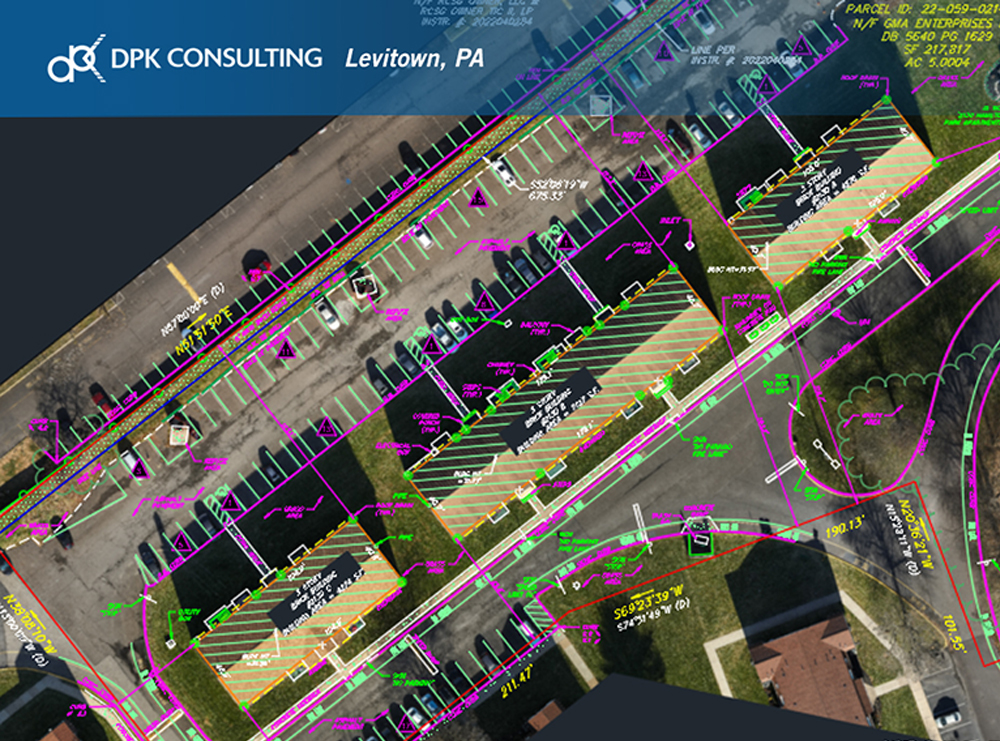

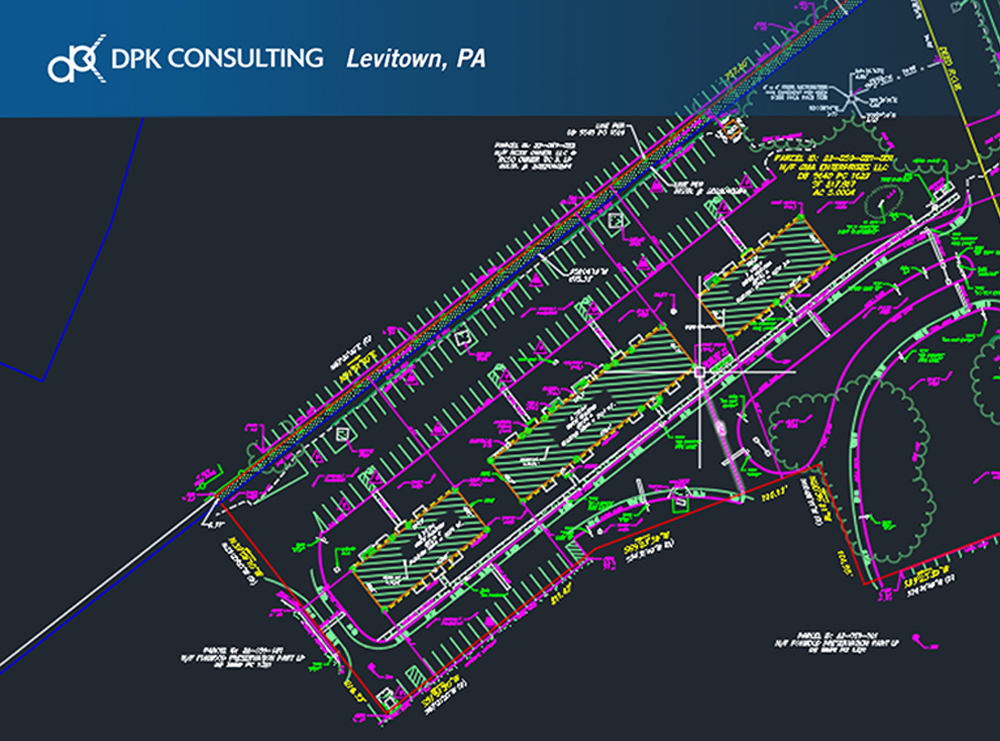

DPK Consulting was recently awarded a large-scale project in Pennsylvania and tasked with delivering an Aerial Topography Survey and Cut-to-Fill Balance for a 350+ acre commercial site. This vast project was ideal for leveraging our advanced Unmanned Aerial Systems (UAS), but it was not without its challenges.

Traditional Surveying Meets Cutting-Edge Technology

Given the extensive area, aerial topography using LiDAR was the clear choice. DPK’s approach involved capturing millions of data points to deliver highly accurate topographic maps and precise cut-to-fill calculations. The aerial mapping depicted site features and contours at a 1-foot interval, using the Pennsylvania State Plane Coordinate System NAD 1983 for horizontal datum and NAVD 1988 for vertical datum.

However, securing ground control points posed some challenges. The site’s rugged terrain and muddy conditions made it impossible to drive in some areas. The DPK team knew that even the best technology sometimes demands good old-fashioned hard work. So, they laced up our tall boots, grabbed our equipment, and navigated the muddy terrain on foot—proving that sometimes, getting dirty is just part of the job, even when flying high with UAS technology.

Aerial Topography with LiDAR

DPK deployed LiDAR-equipped drones to perform aerial mapping, covering every corner of the site. This data was vital in developing the site’s topography and enabled them to create detailed maps. By incorporating both traditional surveying methods and advanced drone

technology, they ensured pinpoint accuracy, providing the foundation needed for subsequent calculations.

Cut-to-Fill Balance Calculations

Using the aerial topography data, DPK performed cut-to-fill balance calculations, determining the precise volume of earth and grading levels. This analysis, prepared under the direct supervision of a licensed Pennsylvania Professional Land Surveyor, adhered strictly to Pennsylvania’s surveying regulations and standards.

Delivering Success by Merging Tradition & Innovation

This PA project showcased the seamless integration of traditional surveying expertise with the latest in UAS technology. By combining these strengths, DPK not only overcame the challenges of difficult terrain but also delivered a precise, timely, and cost-effective solution that sets a new standard for large-scale surveying projects.

To discuss your next project, call 732-764-0100 and ask for James Heiser or Ray Hyman. Alternatively, visit our 24/7 Quick Quote page to upload your scope of work and site reference documents. A DPK project manager will respond promptly.

Get your quote started today!

Some Projects Truly Show the Benefits of Surveying Techniques Combined with the Latest in UAS Technology. This Project is One of Them!

DPK Consulting was recently awarded a large-scale project in Pennsylvania and tasked with delivering an Aerial Topography Survey and Cut-to-Fill Balance for a 350+ acre commercial site. This vast project was ideal for leveraging our advanced Unmanned Aerial Systems (UAS), but it was not without its challenges.

Traditional Surveying Meets Cutting-Edge Technology

Given the extensive area, aerial topography using LiDAR was the clear choice. DPK’s approach involved capturing millions of data points to deliver highly accurate topographic maps and precise cut-to-fill calculations. The aerial mapping depicted site features and contours at a 1-foot interval, using the Pennsylvania State Plane Coordinate System NAD 1983 for horizontal datum and NAVD 1988 for vertical datum.

However, securing ground control points posed some challenges. The site’s rugged terrain and muddy conditions made it impossible to drive in some areas. The DPK team knew that even the best technology sometimes demands good old-fashioned hard work. So, they laced up our tall boots, grabbed our equipment, and navigated the muddy terrain on foot—proving that sometimes, getting dirty is just part of the job, even when flying high with UAS technology.

Aerial Topography with LiDAR

DPK deployed LiDAR-equipped drones to perform aerial mapping, covering every corner of the site. This data was vital in developing the site’s topography and enabled them to create detailed maps. By incorporating both traditional surveying methods and advanced drone

technology, they ensured pinpoint accuracy, providing the foundation needed for subsequent calculations.

Cut-to-Fill Balance Calculations

Using the aerial topography data, DPK performed cut-to-fill balance calculations, determining the precise volume of earth and grading levels. This analysis, prepared under the direct supervision of a licensed Pennsylvania Professional Land Surveyor, adhered strictly to Pennsylvania’s surveying regulations and standards.

Delivering Success by Merging Tradition & Innovation

This PA project showcased the seamless integration of traditional surveying expertise with the latest in UAS technology. By combining these strengths, DPK not only overcame the challenges of difficult terrain but also delivered a precise, timely, and cost-effective solution that sets a new standard for large-scale surveying projects.

To discuss your next project, call 732-764-0100 and ask for James Heiser or Ray Hyman. Alternatively, visit our 24/7 Quick Quote page to upload your scope of work and site reference documents. A DPK project manager will respond promptly.

Get your quote started today!

Try Our 24/7 RFP Solution. Get Your Project Bid Fast!

DPK has developed this simple, 2-step Quick Quote system to streamline your project request and accelerate our response. This form enables you to securely submit your project details, select the specific services you require, upload supporting files, and provide key information needed for a prompt and accurate proposal.

We appreciate the opportunity to support your project. Our high touch communication and multi-service expertise is what defines DPK Consulting. Thank you.

Need Help?

Need something more? Call 732-764-0100 and ask for Ray Hyman.

DPK Quick Quote Form

"*" indicates required fields